Peelply

Peel Ply fabrics may be used to build large composite structures or to facilitate small repairs where a clean, textured surface is desired for additional bonding and finishing operations. A Peel Ply layer also provides pressure to the GRP composite structure during fabrication and cure allowing gas to escape thereby eliminating blisters. Where Peel Ply fabric is used, the laminate will be smoother and will achieve a higher fiber to resin content thus increasing strength. Without Peel Ply, production of vacuum-formed laminates, especially composites made with epoxy/carbon/Kevlar, is hardly possible. Furthermore, excellent non-skid surfaces can be obtained.

Processing

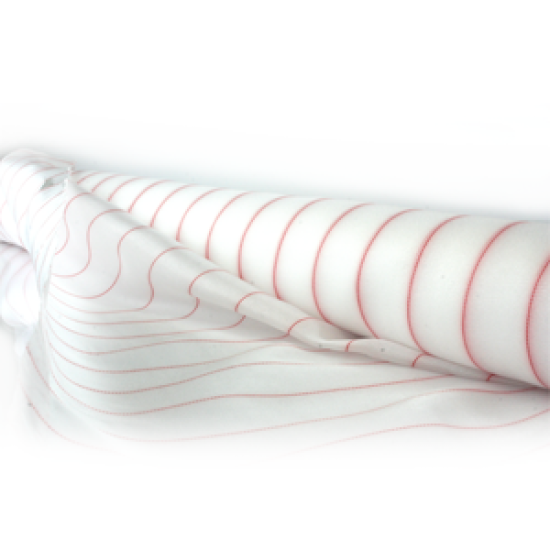

Generally, Peel Ply fabric is inserted as a final layer onto the laminate during fabrication then "peeled away" after cure. Peel Ply fabric will not combine with laminating resins and therefore, should never be allowed to remain on the laminate. Cramer Fabrics' Peel Ply fabrics are woven with intermittent colored warp threads for identification to insure all Peel Ply material is removed after cure.

Laminates can be degassed perfectly since air pockets can be seen under the transparent Peel Ply layer. Air pockets can be eliminated with hand rollers and the escaping air will easily pass through the Peel Ply. Excess resin, which squeezes through Peel Ply, will accumulate on the Peel Ply surface and will be removed later when this fabric is stripped away.

Removal of Peel Ply fabric should be done with great care and pulled at acute angles from the laminate to avoid damage to the laminate and to insure complete separation of the fabric. More force may be required if the laminate is cured under vacuum pressure. In this case, it may be necessary to cut the Peel Ply into thin strips and pull in the warp direction as shown in the illustrations below.

Peelply

VACUUM MATERIALS - Peelply

Peelply - VACUUM MATERIALS | COMPOSITE24

- Stock: In Stock

- Model: peelply

- Weight: 0.09kg

- Dimensions: 100.00cm x 100.00cm x 0.03cm

- SKU: peelply